Please enter your demands, our sales staff will offer you in 6 hours.

Introduction:

This packing unit consists of one vertical packing machine for bagging ,one set linear weigher for weighing , one vertical bucket elevator for feeding ,one platform for supporting weigher and one conveyor for taking off the finished bags .It integrates functions of automatic bag-making, weighing, filling, sealing, printing, punching, cutting and sealing into one. The advanced design has guaranteed this machine suits for different kinds of granules,like rice,beans,seeds,corns,detergent powder and other kind of solid granules. Its adjustment , operation and maintenance are very convenient.

Application:

Sample bags:

Advantages:

|

Combination weigher |

Adopt high precision and high accurate loadcell of famous brand, resolution is improved up to 2 decimal; |

|

Program recovery function can reduce operation failures and support multi-segment weight calibration; |

|

|

No products auto pause function can improve weighing stability and accuracy; |

|

|

100 programs capacity can meet various weighing requirements and user-friendly help menu contributes to easy operation; |

|

|

Linear amplitude can be adjusted independently in the running; |

|

|

Many languages available for global markets. Mechanical Character |

|

|

Weighing type for material detection is available, which can make accurate control of feeding time & material thickness and ensure weighing accuracy; |

|

|

Aluminum thickened middle standing enhances the strength of the machine, making the time for stabilizing hoppers much shorter. |

|

|

Vertical packing machine |

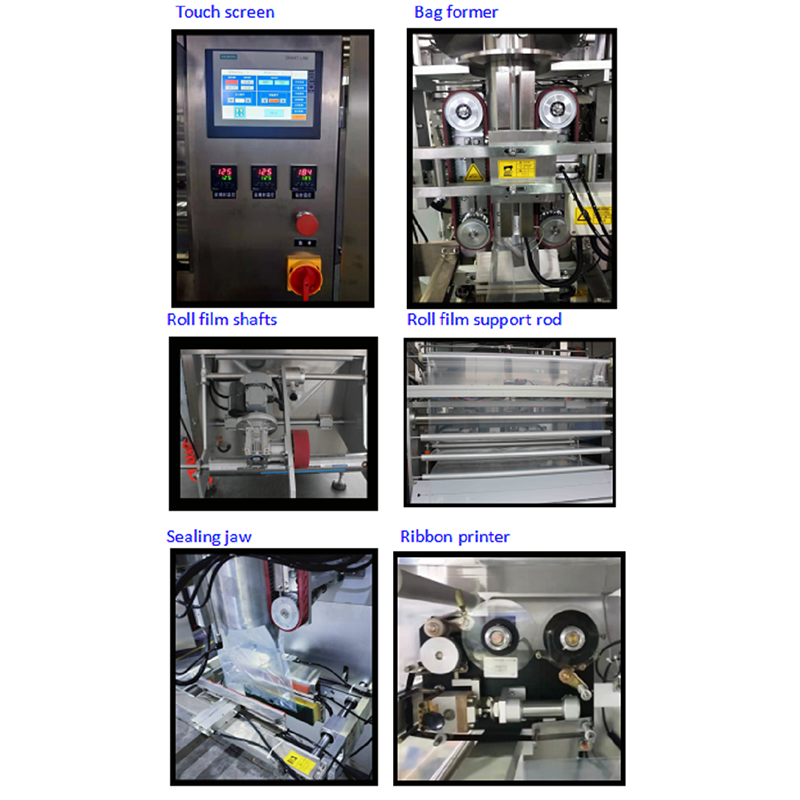

This machine own functions of bag-making,sealing,date printing,cutting,etc.

|

|

Adopts Siemens PLC & Touch Screen,PANASONIC servo motor, Japanese Photo Sensor, Korean Air valve,Schneider electrical components,etc. |

|

|

Can be used for making pillow bag,gusset bag,hole-punching bag, box type bag,etc. |

|

|

Can be installed with ribbon printer, thermal transfer coding machine,label sticking machine for printing dates,letters,QR code,bar code and sticking labels on bag. |

|

|

Automatically form and make a bag by using roll film |

Technical parameters:

|

Model |

Weighing machine |

Bag type/ Bag Material |

Max Roll Film width |

Bag size:(mm) |

Max speed |

|

KY320 |

ZH10 |

Pillow bag,gusset bag,hole punching bag/LDPE film, Laminated film |

320mm |

W(60-150)*L(80-180) |

70BPM |

|

KY420D |

ZH10 |

420mm |

W(80-200)*L(80-280) |

50BPM |

|

|

KY540B |

ZH10/ZH14 |

540mm |

W(120-260)*L(80-340) |

50BPM |

|

|

KY730B |

ZH14 |

730mm |

W(150-350)*L(120-460) |

50BPM |

|

|

KY780B |

ZH14 |

780mm |

W(150-375)*L(120-460) |

40BPM |

|

|

KY1100 |

ZH14 |

1100mm |

W(300-535)*L(300-650) |

10BPM |

Machine components