Please enter your demands, our sales staff will offer you in 6 hours.

Introduction:

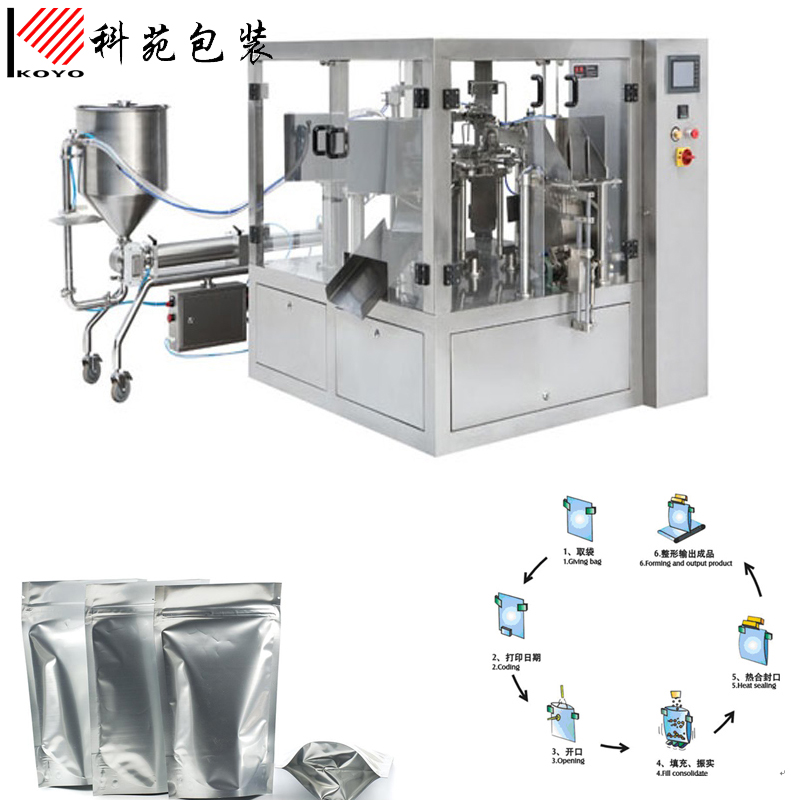

This packing unit consists of one premade bag packing machine for packing ,one set liquid pump for weighing , one liquid storage and pump feeding device and one conveyor for taking off the finished bags .It integrates functions of automatic bag-feeding,bag-opening, weighing, filling, sealing, cooling into one. The advanced design has guaranteed this machine suits for different kinds of granules,like salt,rice and seeds. Its adjustment , operation and maintenance are very convenient.

Application:

Samples bags:

Advantages:

|

Liquid pump |

Cylinder drives piston pump |

|

Products contact parts: 304 S.S |

|

|

With 50L Hopper for products storage. |

|

|

Filling Range: 1000ml-2000ml |

|

|

Weight Accuracy: +/- 0.5% |

|

|

With prevent oil dropping system |

|

|

Premade bag packing machine |

This machine own functions of bag-feeding, bag-opening,sealing,date printing,cooling,etc.

|

|

Easy to operate,adopt advanced PLC from Germany Siemens, mate with touch screen and electric control system, the man-machine interface is friendly |

|

|

Frequency conversion adjusts the speed: this machine uses frequency conversion equipment, can be adjusted within the range according to the needs of reality in production |

|

|

Automatic checking: no pouch or pouch open error, no fill, no seal. the bag can be used again, avoid wasting packing materials and raw materials. |

|

|

Safety device: Machine stop at abnormal air pressure, heater disconnection alarm |

|

|

With independent touch screen for seting parameters |

|

|

Horizontal conveyer style to giving bag: it can put on more bags on the bag storage and have a low requirement about the quality of bags. |

|

|

The width of the bags could be adjusted by electrical motor. Press the control-button could adjust the width of clips, easily operate, and save time. |

|

|

Use no oil vacuum pump, avoid polluting the environment in the production. |

|

|

The opening zipper framework is special in the feature of zipper bag,it can avoid distortion or destroy when open the zipper |

|

|

Product or packing bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food |

Technical parameters:

|

Model |

Weigher/Filler/Dosing system |

Working station |

Bag type |

Bag size:(mm) |

Packaging speed |

|

KYG6-200 |

Piston pump/rotor pump/servo pump |

6 |

Pillow bag, 4 side/ 3 side seal bag, |

W(80-200)*L(100-300) |

Max 40BPM |

|

KYG6-260 |

6 |

W(130-260)*L(100-300) |

Max 30BPM |

||

|

KYG6-300 |

6 |

W(180-300)*L(200-500) |

Max 20BPM |

||

|

KYG8-200 |

8 |

Pillow bag, 4 side/ 3 side seal bag, Stand up bag with Zipper,doy bag |

W(80-200)*L(100-300) |

Max 40BPM |

|

|

KYG8-260 |

8 |

W(130-260)*L(100-300) |

Max 30BPM |

||

|

KYG8-300 |

8 |

W(180-300)*L(200-500) |

Max 20BPM |